Application Overview

★The boiling granulator is mainly used for powder material mixing, granulation, drying, and particle "top spraying" coating operations in industries such as medicine, food, and chemical engineering. For example, tablet granules, instant drinks, and seasoning granules.

★This machine is designed and manufactured according to the standard JB20014-2004 "Medicinal Boiling Granulator".

Equipment characteristics

★The mixing granulation drying step method meets the process requirements.

★Double capture filter bag system, thorough ash cleaning.

★Multi fluid atomizer ensures uniform particle formation and extremely low powder content.

★Optional explosion-proof design with 2 bar.

★Design, manufacture, and engineering configuration layout according to GMP specifications.

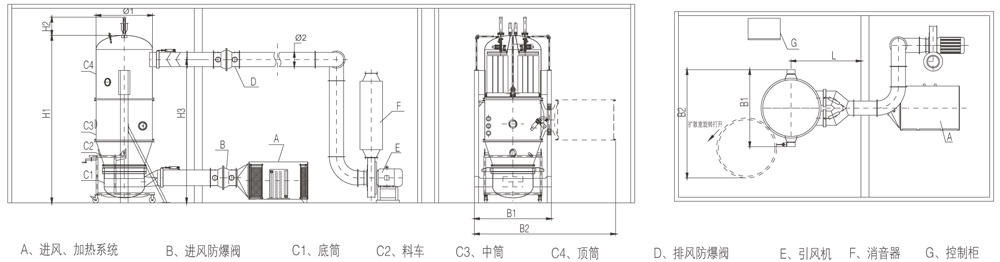

Outline Dimensional Drawing

Project specifications | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | 800-1000 | ||

Volume of raw material container | L | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 550 | 670 | 1000 | 1500 | Design according to user requirements | |

Production capacity | Kg/batch | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | ||

Steam | Pressure | Mpa | 0.4-0.6 | ||||||||||||

Consumption | Kg/h | 10 | 18 | 35 | 60 | 99 | 120 | 130 | 140 | 161 | 180 | 310 | 400 | ||

Fan power | kw | 3 | 4 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22 | 30 | 45 | ||

Electric-heating power | kw | 6 | 9 | ||||||||||||

Noise | dB | Fan isolation processing noise below 75 decibels | |||||||||||||

Compressed air | Pressure | Mpa | 0.6 | ||||||||||||

Consumption | m3/min | 0.3 | 0.3 | 0.6 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 0.9 | 1.1 | 1.3 | 1.5 | ||

Host size | H1(mm) | 2600 | 2600 | 2100 | 2250 | 2250 | 2850 | 2850 | 2850 | 3050 | 3300 | 3500 | 3850 | ||

H2(mm) | 250 | 320 | 420 | 490 | 540 | 590 | 640 | 690 | 790 | 890 | |||||

H3(mm) | 1900 | 2050 | 2050 | 2600 | 2600 | 2600 | 2600 | 3000 | 3280 | 3630 | |||||

B1(mm) | 640 | 740 | 1010 | 1160 | 1320 | 1460 | 1560 | 1660 | 1760 | 1860 | 2060 | 2260 | |||

B2(mm) | 1500 | 1800 | 2060 | 2460 | 2660 | 2800 | 3060 | 3260 | 3660 | 4060 | |||||

?1(mm) | 300 | 400 | 550 | 700 | 860 | 1000 | 1100 | 1200 | 1300 | 1400 | 1600 | 1800 | |||

?2(mm) | 150 | 180 | 180 | 180 | 250 | 280 | 280 | 280 | 315 | 315 | 355 | 385 | |||

L(mm) | 850 | 1000 | 1100 | 1250 | 1530 | 1530 | 1530 | 1650 | 1650 | 1650 | 1750 | 1850 | |||

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.