Application Overview

This machine is used for drying wet granular materials in fields such as pharmaceuticals, chemicals, feed, and food.

Equipment characteristics

★ The fluidized bed has a circular structure to avoid dead corners.

★ The bed is equipped with stirring to avoid the agglomeration of damp materials and the formation of ditches during the drying process.

The top mounted bag filter is made of anti-static special fibers, ensuring safe operation.

★ Dumping material, convenient, rapid and thorough.

★ Sealing negative pressure operation, designed according to GMP specifications.

★ This machine can also be designed and manufactured for automatic feeding and discharging according to requirements.

★ The drying speed is fast, the temperature is uniform, and the drying time for each batch is generally 20-30 minutes.

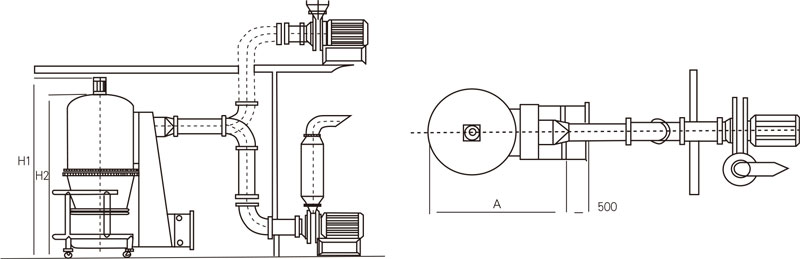

Installation reference diagram

Project specifications | 60 | 100 | 120 | 150 | 200 | 300 | 500 | 800-1000 | ||

Inventory | kg/batch | 60 | 100 | 120 | 150 | 200 | 300 | 500 | Design according to user requirements | |

Fan power | kw | 7.5 | 11 | 11 | 15 | 22 | 30 | 37 | ||

Stirring power | kw | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | ||

Stirring speed | rpm | 11 | ||||||||

Steam | Pressure | Mpa | 0.4-0.6 | |||||||

Consumption | kg/h | 141 | 170 | 210 | 240 | 282 | 366 | 451 | ||

TIME | min/batch | 15-90 | ||||||||

Host size | H1 | mm | 2676 | 2842 | 2862 | 2940 | 3014 | 3300 | 3650 | |

H2 | mm | 2366 | 2532 | 2552 | 2630 | 2704 | 2800 | 3150 | ||

A | mm | 2440 | 2540 | 2540 | 2740 | 2840 | 2940 | 3140 | ||

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.