Summary

Paddle type dryer is a low-speed stirring dryer that sets stirring paddles inside the equipment, allowing materials to fully contact the heat carrier and surface under the stirring of the paddles, thus achieving the drying purpose. The structure is generally horizontal, double axis or four axis.

Paddle type dryers are divided into hot air type and heat transfer type. The hot air type refers to the drying process where the heat carrier (such as hot air) comes into contact with the dried material and is dried. In the conductive type, the heat carrier does not directly contact the dried material, but rather the hot surface comes into contact with the material. The advantages of conductive type are that materials are not easily contaminated, the exhaust volume is small, the thermal efficiency is high, and the volume is relatively small, which is conducive to energy conservation and preventing air pollution.

Applicable scope

Drying of plastic resin products, inorganic drugs, fertilizers, food, chemical fibers, dyes, starch, sewage pipes, sludge, and other products, such as vinyl chloride resin, nylon polyethylene, polypropylene starch, sodium chloride, sugar, iron oxide, feldspar, caustic soda powder, and various powder particles and paste materials.

Characteristic

★ The equipment is compact, with a small footprint, high thermal conductivity, and excellent thermal efficiency, generally reaching 80% -90%, making it an energy-saving device.

★ The equipment has low rotational speed and low crushing ability for granular and flaky materials.

★ Wide adaptability to materials, high operational flexibility, and adjustable material retention time of several minutes to several hours.

★ The auxiliary equipment is simple, with low investment and low operating costs.

★ One machine is versatile and can be used for drying, cooling, gas recovery, reaction heating (pre sterilization) and other process operations.

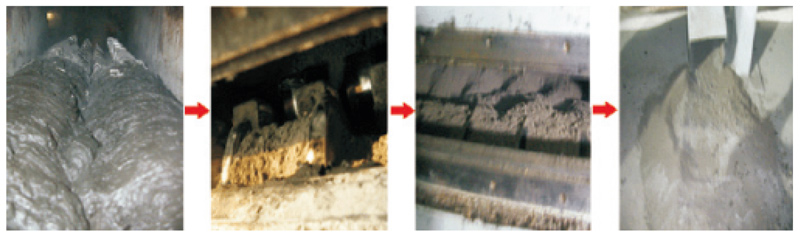

Drying process

Model Item | JYG-3 | JYG-9 | JYG-13 | JYG-18 | JYG-29 | JYG-41 | JYG-52 | JYG-68 | JYG-81 | JYG-95 | JYG-110 |

Heat transfer area (m3) | 3 | 9 | 13 | 18 | 29 | 41 | 52 | 68 | 81 | 95 | 110 |

Effective volume (m3 ) | 0.06 | 0.32 | 0.59 | 1.09 | 1.85 | 2.8 | 3.96 | 5.21 | 6.43 | 8.07 | 9.46 |

Speed range (r.m.p) | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-10 |

Power (Kw) power | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 45 | 55 | 75 | 95 |

Body width A (mm) | 306 | 584 | 762 | 940 | 1118 | 1296 | 1474 | 1652 | 1828 | 2032 | 2210 |

Width B (mm) | 736 | 841 | 1066 | 1320 | 1474 | 1676 | 1854 | 2134 | 2268 | 2438 | 2668 |

Body length C (mm) | 1956 | 2820 | 3048 | 3328 | 4114 | 4724 | 5258 | 5842 | 6020 | 6124 | 6122 |

Total length D (mm ) | 2972 | 4876 | 5486 | 5918 | 6808 | 7570 | 8306 | 9296 | 9678 | 9704 | 9880 |

Incoming and outgoing distance E (mm) | 1752 | 2540 | 2768 | 3048 | 3810 | 4420 | 4954 | 5384 | 5562 | 5664 | 5664 |

Centre-to-centre spacing F (mm) | 380 | 380 | 534 | 610 | 762 | 915 | 1066 | 1220 | 1220 | 1220 | 1220 |

Height G (mm) | 762 | 838 | 1092 | 1270 | 1524 | 1778 | 2032 | 2362 | 2464 | 2566 | 2668 |

Air intake N(Inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 2 |

Water inlet O(Inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 2 |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.