Application Overview

Powder or masterbatch in a rotating fluidized bed is subjected to annular air buoyancy, rotating centrifugal force, and self gravity, forming a circumferential rope strand shape. The adhesive or coating liquid is sprayed into the material layer to form highly spherical pellets or a continuous and uniform coating film.

Equipment characteristics

★Integrating mixing, pelletizing, granulation, and drying, reducing process steps and pollution links, and reducing labor intensity.

★The internal and external surfaces of the equipment are smooth and clean, without dead corners, which is easy to clean and meets the requirements of "GMP".

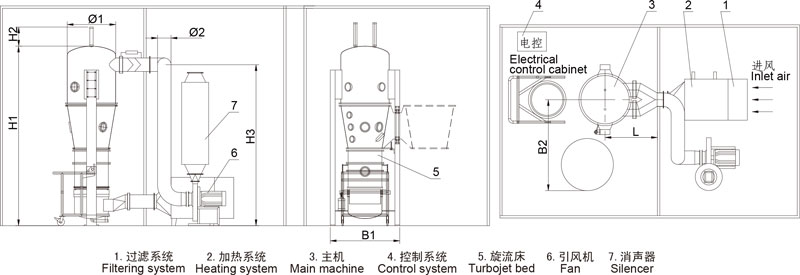

Outline Dimensional Drawing

Project specifications | 1.5 | 10 | 20 | 30 | 60 | 120 | ||

Volume of raw material container | L | 5 | 30 | 60 | 105 | 180 | 420 | |

Inventory | kg/batch | 0.5-1.5 | 3-10 | 8-20 | 10-30 | 20-60 | 40-120 | |

Rotating motor power | kw | 0.55 | 1.5 | 4 | 5.5 | 7.5 | 11 | |

Fan power | kw | 4 | 5.5 | 7.5 | 15 | 18.5 | 22 | |

Steam | Pressure | Mpa | 0.4-0.6 | |||||

Consumption | Kg/h | 6KW | 42 | 84 | 166 | 250 | 332 | |

Compressed air | Pressure | Mpa | 0.6 | |||||

Consumption | m3/min | 0.3 | 0.6 | 0.6 | 1.1 | 1.8 | 2.4 | |

Host size | H1(mm) | 2600 | 2250 | 2850 | 2850 | 3300 | 3500 | |

H2(mm) |

| 320 | 490 | 590 | 690 | 790 | ||

H3(mm) |

| 2050 | 2600 | 2600 | 3080 | 3280 | ||

?1(mm) | 400 | 700 | 1000 | 1200 | 1400 | 1600 | ||

?2(mm) | 180 | 180 | 280 | 280 | 280 | 315 | ||

B1(mm) | 1650 | 1160 | 1460 | 1660 | 1860 | 2060 | ||

B2(mm) |

| 1800 | 2460 | 2860 | 3260 | 3660 | ||

L(mm) |

| 1250 | 1530 | 1650 | 1650 | 1750 | ||

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.